Content

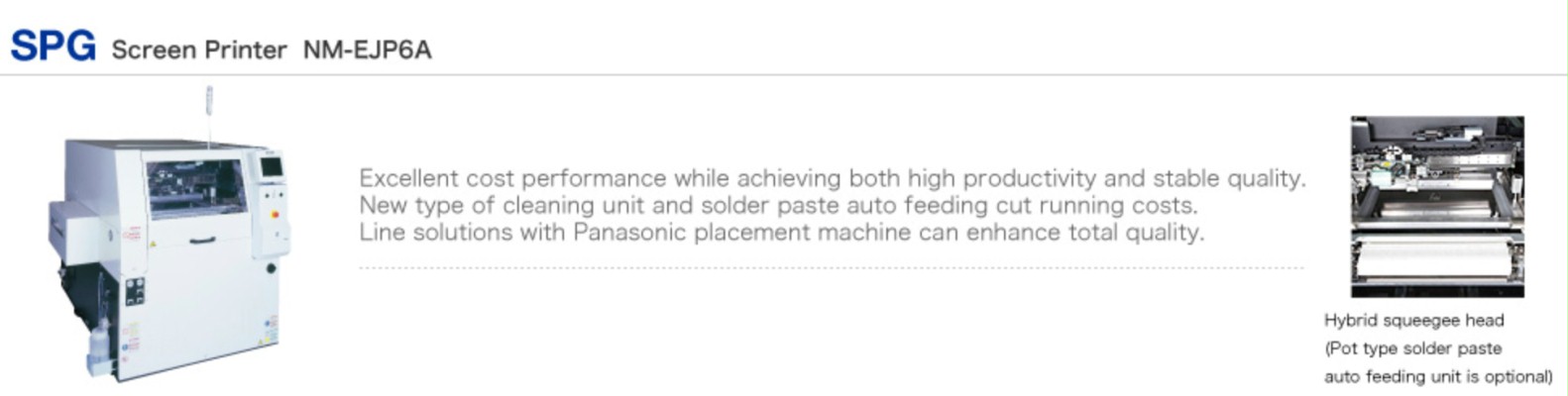

SMT Screen Printing Machine

❙ Features of Panasonic PCB Printing Machine

Features that enable high productivity and stable quality

1. Hybrid squeegee head

Hybrid squeegee head, which has a good track record with our highly functional models, is equipped as standard.

Together with stabilizing rolling solders, printing cycle time is reduced.

2. High-speed mask cleaning

New-type cleaning mechanism reduces paper consumption. Moreover, parallel processing of transfer and cleaning cuts back loss time.

3. 3 conveyors equipped

3 conveyors are equipped as standard for shorter PCB exchange time.

(supported PCB length up to MAX 350mm)

Perforated pot type automatic solder supply

Automation of solder supply allows for labor savings and uninterrupted operation.

・Maintenance-free

Cleaning of spatulas/nozzles is unnecessary

・Reduction of discarded solder

e.g., solder attached on spatulas or inside nozzles

・Uninterrupted operation

2-pot-type continuous supply

Sealed head

Press-fit of solder becomes possible, allowing fine pitch/through hole printing.

PCB pickup blower (switch type)

Printing transcription is improved through the use of blower to create airflow pathways from metal mask to PCB.

One-touch support pins

Support unit for batch replacement.

While checking on PCB, you can set magnet pins at desired locations.

Automatic mask positioning

Based on PCB data, the Y-directional mask position is automatically registered.

According to the correction data of shifted printing positions analyzed by solder paste inspection (APC correction data), it corrects printing positions(X ,Y ,θ).

*3D inspection equipment of other companies can also be connected.

* Please inquire with your sales representative for more details

Connect with upper system(LNB,LWS…)

• Automatic changeover

• Component verification(solder/mask/squeegee…)

• Trace data output

*About the specification and system configuration,please refer to the“Specification”for details.

| Product name | SMT LED Printing Machine Panasonic PCB Screen Printer |

| Model | Panasonic SPG |

| PCB dimensions (mm) | L 50 x W 50 to L 510 x W 460 |

| PCB exchange time | 6.5 s (incl. PCB recognition) (when PCB is L350 x W300 ) *1 |

| Repeatability | 2Cpk ±5.0μm 6σ (±3σ) |

| Screen frame dimensions (mm) | L 736 x W 736, L 650 x W 550, L 600 x W 550*2 |

| Electric source | 1-phase AC 200, 220, 230, 240 V ±10V 1.7 kVA*3 |

| Pneumatic source |

0.5 MPa, 30 L/min (A.N.R.), (motor vacuum spec), 400L/min (A.N.R.) (ejector vacuum spec) |

| Dimensions (mm) | W 1 580 x D 1 800 *4 x H 1 500 *4 |

| Mass | 1 500 kg*5 |

*1: PCB exchange time varies depending on the machine in the pre-process and the post process, the PCB size, the use of a PCB pressing-down unit and so forth.

*2: For mask specifications, please see the specification.*3: Including blower and vacuum pump"Option"

*4: Except for the signal tower and the touch panel.

*5: In case of full options

*Values such as cycle time and accuracy may vary depending on operating conditions.

*Please refer to the ‘‘Specification” booklet for details.

❙ Company Profile

ETA is the SMT machine supplier with professional 25-year-experienced sales and after sales team, providing SMT solutions including pick and place machine, reflow oven, SMT stencil printer, SMT line and wave soldering machine.

We also is the partner of JUKI pick and place machine and Hanwha/Samsung pick and place machine, can provide the best SMT technical services and accessories support for JUKI, Hanwha/Samsung, YAMAHA, PANASONIC brands.

Successful Experience:

Eta's Customer In 35 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

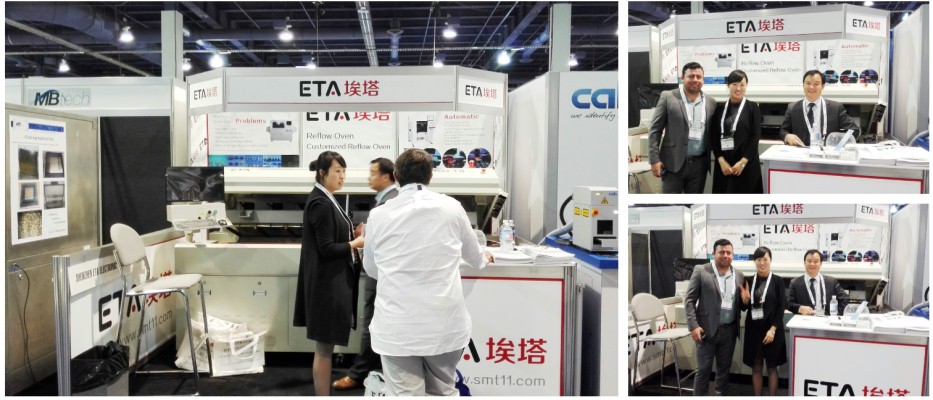

❙ ETA SMT Machine Exhibition

❙ ETA SMT Machine Certificate

❙ ETA Global Service

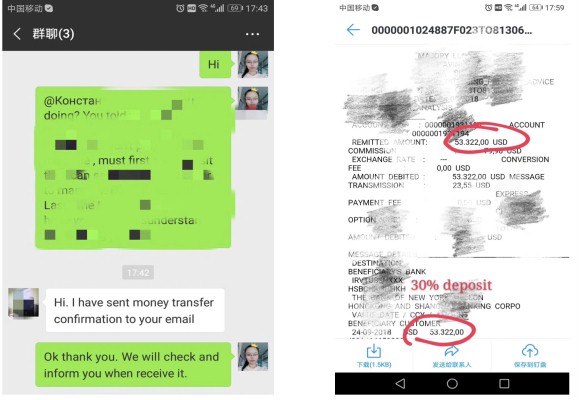

❙ Customers' Feedback

❙ FAQ

❙ Panasonic Pick and Place Machine Video

If you could not find any similar items you want, you may send some photos to us. because our catalog and website haven't included all of our products.